Custom Western Boots

Many western boots are worn for horse riding. The basic shape is directed at protecting the rider’s lower leg and feet and assisting him in staying mounted on a horse. Such boots must be designed with their use kept in mind, as well as the abuse and exposure they will receive. Such boots must protect the feet from, and be able to withstand the effects of, not only spring rains and summer dust, but also the acid bath of soil in corrals and holding pens.

Many people wear western style boots not for horse-riding but to somehow connect to the idea of the west. As such, the western boot must still incorporate certain elements, the high heel and high shaft around the lower leg, but beyond that, they play an important part in supporting the fashion tastes of their wearers. Some of the boots will be used by riders on horses, but many will be worn in boardrooms or on stage.

Today’s world of mass-produced items brings us, among many things, mass produced western boots at a low price. So why buy a custom-made boot? It’s a question of fitting the customer to the boot, or the boot to the customer. Mass production produces boots to fit only a few standard sizes. The mass-produced boot is designed more or less to fit feet of very specific width and length. The customer seeks a boot that “fits,” but this means mostly a boot that he fits into, thus the customer must fit the boot. If he doesn’t fit exactly, he will put up with some discomfort: pressure here, pinches there, rubbing and chafing.

In the case of the custom bootmaker, the goals are different. He starts with the customer, and then fits the boot to him. The boot is designed to fit the individual customer. This does not only mean to fit the feet, but his or her personal needs and tastes.

Factory-made boots have certain qualities that, for a limited budget, may be suitable. They tend, however, to be computer perfect, cookie cutter stamped with hundreds of boots looking essentially the same, like so many vanilla wafers. You can buy the same boot in a discount store in Houston, San Francisco or Atlanta. “They lose their regionality,” says Hot Springs custom bootmaker Jim Bultsma. The impact of regional tastes and influences that might be apparent in the work of a custom bootmaker is lost.

“Some people want something with individual character to it,” says Bultsma. “They want something that someone spent time on. Someday people will rise up against the cookie cutter world of mass-produced clothing, boots, and everything. Already I think I see signs that they are tired of it, bored by it.” The unique look of a boot made by a custom bootmaker working with an individual client is still possible. By working with the bootmaker the customer has some control over style, leather type, pattern, and color.

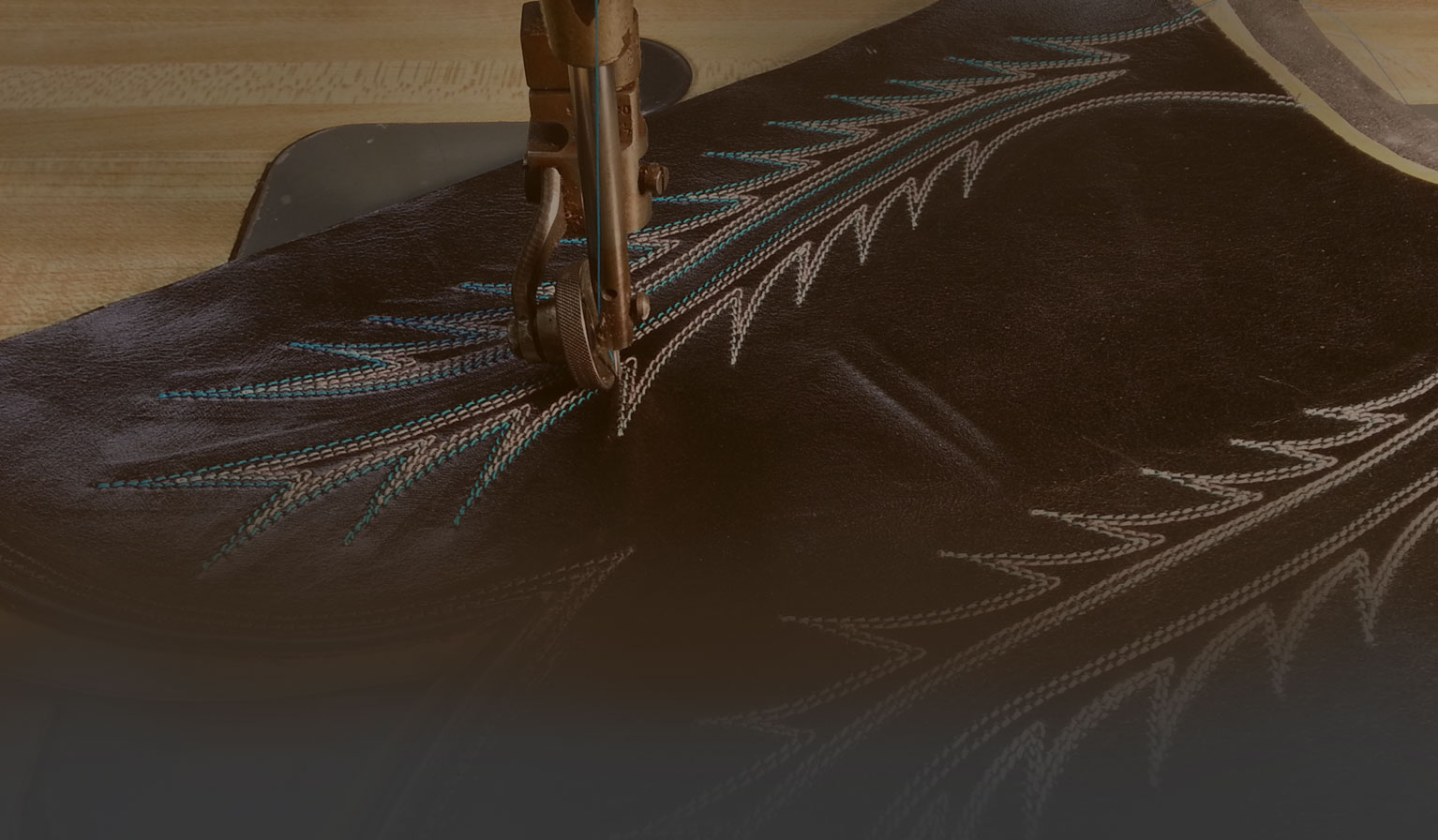

The construction of custom-made boots for individual clients also provides the opportunity for them to select from a wide range of leather textures and colors as well as boot styles. Fine leather, quality stitchwork, special inlay and overlay patterns may be used to help the custom boot wearer look good and speak out as an individual.

Handcrafted by a skilled, knowledgeable craftsman, a custom boot takes longer to build, often ten times as long as a factory made boot. It costs more because of the time involved to make a boot that fits the customer, and not make the customer fit the boot.